Cup Candle &

Nachhaltige, plastikfreie Innovationen für eine echte Kreislaufwirtschaft

Seit 2015 setzen Cup Candle und ecoscin Maßstäbe bei nachhaltigen Alternativen zu Plastik. Unsere patentierten Lösungen sind vollständig recycelbar, kompostierbar (heim- & industriell) und bestehen aus nachwachsenden Rohstoffen.

Unsere Vision: Eine echte, plastikfreie Kreislaufwirtschaft – für Industrie, Handel und Umwelt.

Gemeinsam mit Partnern aus Industrie und Handel entwickeln wir faserbasierte, kreislauffähige Produktlösungen – auf Basis unseres biobasierten Coatings

– plastikfrei, kompostierbar, recycelbar und anpassbar an Ihre Anwendung.

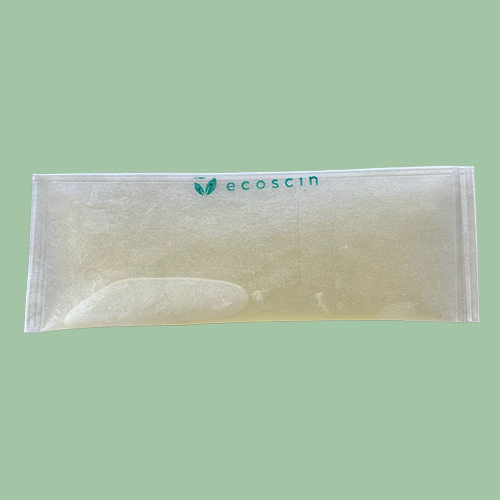

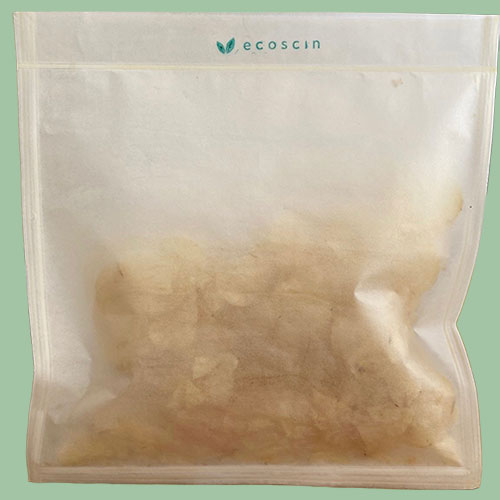

Natürliche Beschichtungssysteme für Food & Non-Food

Coating – Biobasierte Innovation (Patentiert)

Plastikfreie Verpackung für moderne Industrie

Nachhaltige Lösungen für die Kerzenindustrie

Kreislaufwirtschaft als neuer Standard

Verbraucher und Handel fordern zunehmend Verpackungen, die:→ Plastikfrei

→ Recycelbar

→ Biologisch abbaubar sind. Unsere Innovationen helfen Unternehmen, diesen Wandel sichtbar und wirtschaftlich umzusetzen.

Ihre Vorteile mit Cup Candle

& ecoscin→ 100 % plastikfreie Produktlösungen

→ Recycelbare & biologisch abbaubare Materialien

→ Nachhaltige Entwicklung seit 2015

→ Industrietaugliche Alternativen zu Plastik